SA`s Dynohub has a bearing 629UU.

What is the meaning of "UU" ?

From FAG I know 629 ZZ, 629 2RS

ZZ: 2 cover plates

2RS: 2 seal washers

Bearing 629UU

Re: Bearing 629UU

DU and UU are suffix codes that are used by some manufacturers (I think) to denote rubber seals. The '2RS' code is not a universal designation, although it is used by more than one manufacturer.

This is a 6004-UU bearing

AFAICT 'UU' = 'LLB' ~ '2RS'

sometimes the equivalence of specification is truly in one direction only, i.e. one manufacturer's '2RS' specification is actually better than another's, or has within it an implicit tolerance on the fitted diameters.

FWIW most 2RS bearings are ~1/3 filled with grease so that they may rotate at 10000rpm without burping it out. This bearing fill is inadequate (in both quantity and quality) for low speed applications like bicycle hubs, but economies of scale mean that whatever is cheapest may get fitted anyway. If fitting new bearings of this sort, I think it is a good idea to remove one seal (the one that will end up inside the hub), pack the bearing with high quality waterproof grease, then either

a) leave the seal out and flood the hub internal with a suitable lubricant (semi-fluid grease or oil depending on how good the seals are), for a 'normal hub' or

b) replace the inner seal (for a hub generator).

A small amount of grease will escape from the bearing if it has been filled, but what remains is usually still more than it had originally.

BTW I would not expect a 2RS type seal to work perfectly if fitted to both sides of a hub generator because there is a large trapped volume of air inside the hub and this volume has to 'breathe' somewhere and that somewhere is via the bearings. Possibly SA have fitted a shielded (not sealed) bearing on the brake side of the hub and this is where the hub will breathe, hopefully without consequent water ingress.

cheers

This is a 6004-UU bearing

AFAICT 'UU' = 'LLB' ~ '2RS'

sometimes the equivalence of specification is truly in one direction only, i.e. one manufacturer's '2RS' specification is actually better than another's, or has within it an implicit tolerance on the fitted diameters.

FWIW most 2RS bearings are ~1/3 filled with grease so that they may rotate at 10000rpm without burping it out. This bearing fill is inadequate (in both quantity and quality) for low speed applications like bicycle hubs, but economies of scale mean that whatever is cheapest may get fitted anyway. If fitting new bearings of this sort, I think it is a good idea to remove one seal (the one that will end up inside the hub), pack the bearing with high quality waterproof grease, then either

a) leave the seal out and flood the hub internal with a suitable lubricant (semi-fluid grease or oil depending on how good the seals are), for a 'normal hub' or

b) replace the inner seal (for a hub generator).

A small amount of grease will escape from the bearing if it has been filled, but what remains is usually still more than it had originally.

BTW I would not expect a 2RS type seal to work perfectly if fitted to both sides of a hub generator because there is a large trapped volume of air inside the hub and this volume has to 'breathe' somewhere and that somewhere is via the bearings. Possibly SA have fitted a shielded (not sealed) bearing on the brake side of the hub and this is where the hub will breathe, hopefully without consequent water ingress.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Bearing 629UU

Thanks a lot

Which part of the bearing normally is pressed in , the inner or the outer ring?

they use 6000UU on the brake side

Which part of the bearing normally is pressed in , the inner or the outer ring?

Brucey wrote: Possibly SA have fitted a shielded (not sealed) bearing on the brake side of the hub and this is where the hub will breathe, hopefully without consequent water ingress.

they use 6000UU on the brake side

Re: Bearing 629UU

rofan wrote:Thanks a lot

Which part of the bearing normally is pressed in , the inner or the outer ring?

normally the outer; the inner is usually trapped on axle shoulders by the locknuts.

Brucey wrote: Possibly SA have fitted a shielded (not sealed) bearing on the brake side of the hub and this is where the hub will breathe, hopefully without consequent water ingress.

they use 6000UU on the brake side

OK... this probably isn't harmful in its own right, but may mean that water will eventually get in via the other bearing; I can't see that there is any provided vent in the hubshell, so (unless air is passing down the axle slot for the wire) there must be air burping in and out via the bearings....

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Bearing 629UU

rofan wrote:I found an overview

that is a good chart, but it isn't quite complete for all manufacturers. IIRC there used to be a similar chart in the SKF master catalogue; I don't know if there still is.

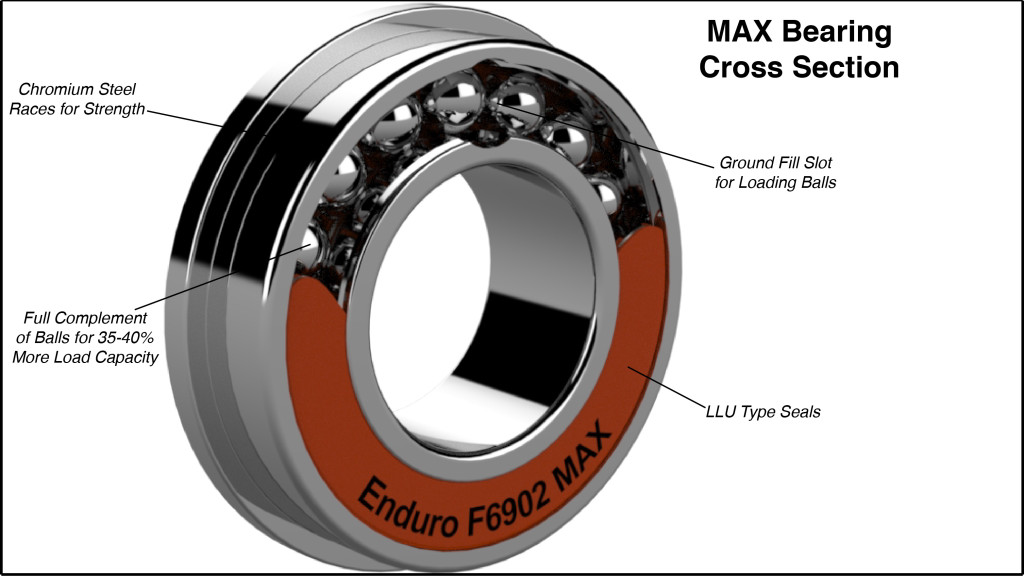

I did a bit of looking about too and as previously noted LLU = UU and this normally means that there is a double-lip seal present both sides of the bearing. Enduro bearings (for example) are given the LLU suffix. This can be (loosely) similar to a 2RS bearing but caveat emptor...

A good quality LLU bearing ought to be a better than the same manufacturer's '2RS' bearing, with a variation to the lip seal design. But the 2RS designation is widely abused; if you get a quality (say SKF) bearing with 2RS designation it will have very effective rubber contact seals but from some other off-brand manufacturers... not so much. Often if you pop the 'seal' out there is no flexible lip at all, and sometimes you can see that the 'seal' isn't even close to making contact;

this is meant to be a 2RS bearing; it might as well have metal shields IMHO; you can see a gap where the seal is meant to contact....

BTW good 2RS sealed bearings will only carry on working as long as the seal lips are in contact and the seal lips have a film of lubricant underneath them. Without the lube film the lips quickly wear out and then the seals become ineffective. In high speed applications the limited grease fill in most bearings is no problem; the grease becomes mobile inside the bearing and it will wet the seal lips. However in low speed applications like bicycles the grease does not become mobile in the same way, so an increased grease fill (preferably of a semi-fluid grease IMHO, or frequent applications of lube externally) are required to keep the seal lips happy.

Arguably a UU or LLU bearing benefits from external lube because if the inner lip is working, It may starve the outer lip of lube.

Note also that not all bearings are sealed in the way you might expect; suspension pivots benefit from the use of 'full complement' bearings in which there are almost twice as many balls as a standard deep groove radial bearing; the balls are loaded through loading slots. These bearings are often no good for high speeds but they are great for suspension pivots. Some folk market these bearings as LLU or 2RS sealed, and sometimes they are. However oftentimes they might as well not be because the loading slots are not designed properly, e.g.

here there is no way the seals can work; the loading slot is too deep. If you use two bearings of this sort in a housing, you can have the loading slots on the inside of the housing and then the compromised seals are not an issue. Unfortunately most suspension pivots are not like this; crud can access both sides of each bearing with equal facility, so some additional seals/shields can help.

Some DIY things you can do;

1) as previously mentioned; refill bearings with grease, to get to 90% fill as recommended for low speed applications.

2) dispense with the inner bearing seals on a hub bearing set and load the hub with oil and/or SFG, and/or fit a lube port.

3) you can make your own full complement bearings; you can grind loading slots into any standard deep groove bearing using a dremel tool. Very many standard bearings use balls that are in one of the common sizes (amazingly a lot of metric cartidge bearings use imperial sized balls inside....) Often it is necessary to provide an external seal to protect the bearings properly.

4) seal upgrades; ZZ (shielded) bearings often (but not always) use the same inner and outer races as 2RS variants. If you do 2) enough times you wind up with a stash of spare seals; oftentimes these come in handy for upgrading ZZ bearings or fitting better seals/replacing inferior ones etc.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~